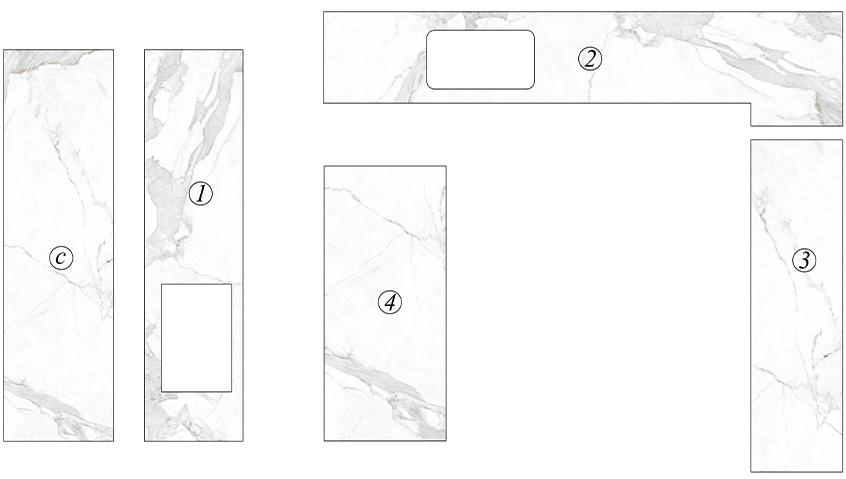

Cutting plan

In the project space, configure piece by piece:

1) Choose the texture (material + finish) of the piece

2) Fill in the dimensions (length, width, thickness of the material excluding overhang)

3) Choose a finish for each visible edge (solid, drop, jamb).

4) Add as many openings for sinks and cooktops as necessary and enter the types and dimensions of

the openings

Let us guide you to establish a cutting plan

The maximum dimension of an uncut slab of material is 320 mm long and 150 mm wide, plans larger than this will need to include joints. For worktops, the joints can be as tight as possible and can be almost invisible on some textures. It will be necessary to cut your worktop into slabs whose lengths and widths are within these dimensions.

This kitchen includes a worktop with 3 pieces (1, 2, 3), an island with one piece

(4) and a credenza (c).

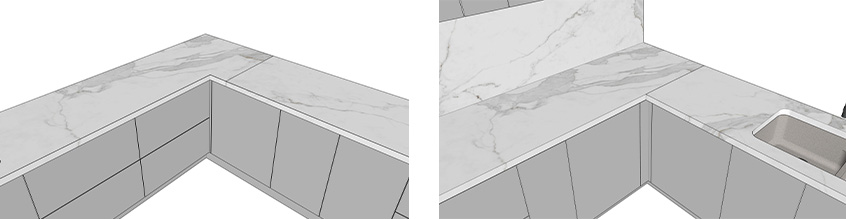

We propose two types of angular connections: A connection composed of two simple rectangular

pieces (as for pieces 2 and 3) or a connection composed of an angular piece in

L shape and a simple rectangular piece

(as for pieces 1 and 2).

You have the possibility to make angular connections either with two simple rectangular pieces or with an L-shaped piece and a simple rectangular piece.

The cutting plan of this kitchen includes 5 forms for the 3 worktops (1),(2),(3), for the island (4) as well as for the credenza (c)) :

- Four forms of rectangular pieces Simple: credenza (c), worktop (3) and island (4)

- One angular piece form (right angle) for the worktop (2)

Add to this, two accessory forms:

- A rectangular sink form with rounded corners

- A baking sheet form

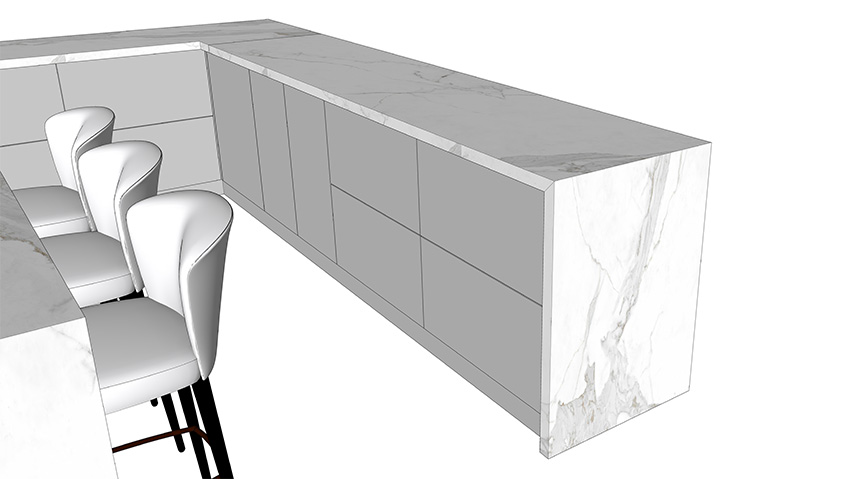

Do not add a piece for the jambs of the pieces (3) and the island (4), they are to be filled in the description of the edge finish of the plate in question. In this example:

Island :

- Edge 1 and 3: Mitered edge (45°)

- Edge 2 and 4: Mitered edge (45°)

Work surface (3)

- Edge 1: -

- Edge 2: -

- Edge 3: Mitered edge assembled (45°)

- Edge 4: Mitered sill (45°)